[ベスト] yield stress equation 114504-Shear yield stress equation

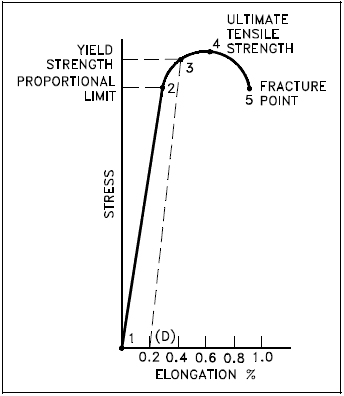

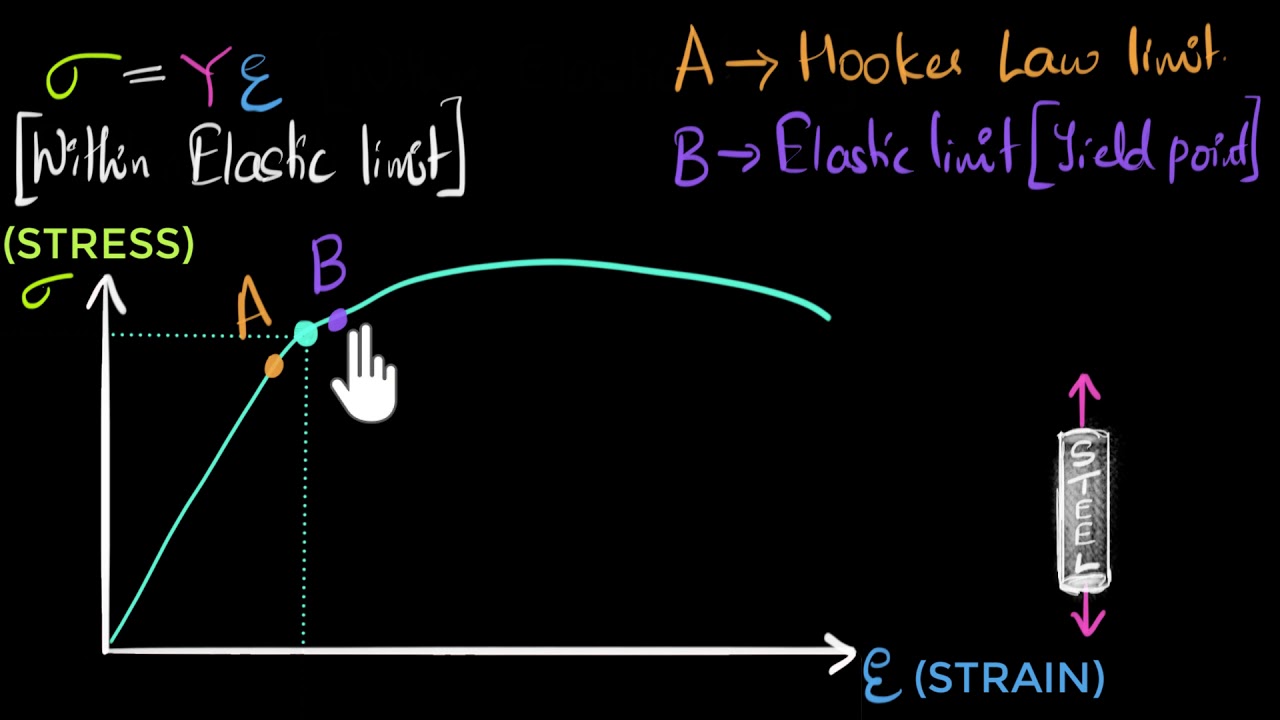

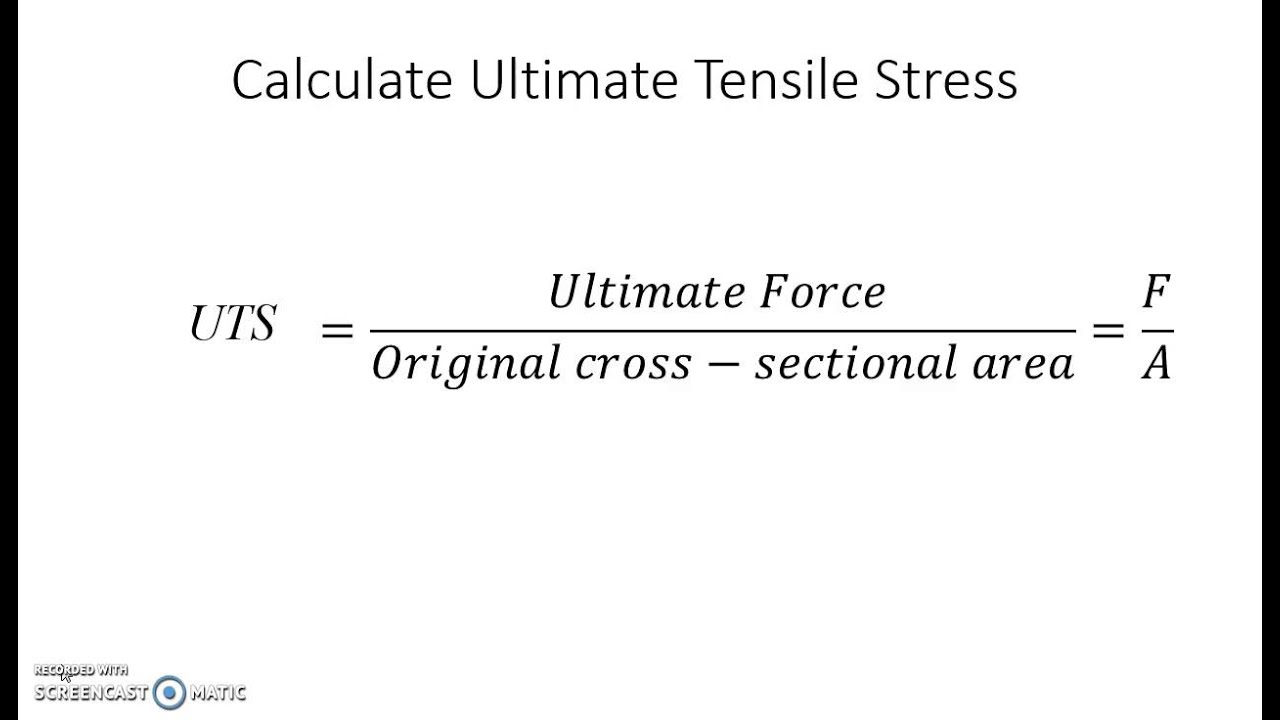

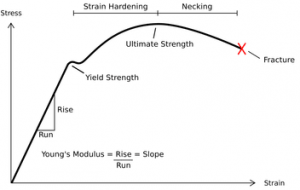

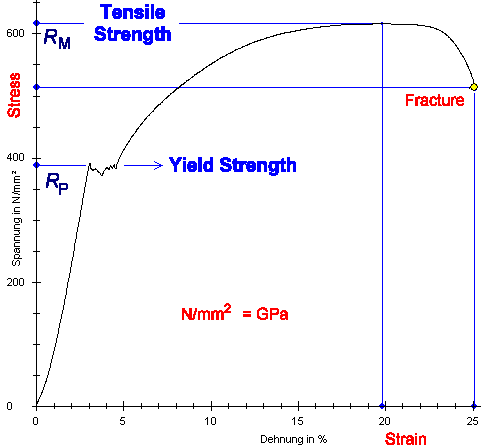

Tensile stress Tensile strength It is defined as force per unit area which is associated with stretching and denoted by σ It is defined as the amount of tensile stress a material can withstand before breaking and denoted by s The formula is σ = F/A Where, σ is the tensile stress;The true stress and true strain are defined below For accurate calculations, the true stresstrue strain curve for the metal should be drawn to determine the yield strength Figure 16 redrawn on true stresstrue strain axes would look like the one shown in Fig 18YP ⇒ Yield Point Stress at which there are large increases in strain with little or no increase in stress Among common structural materials, only steel exhibits this type of response σ YS ⇒ Yield Strength The maximum stress that can be applied without exceeding a specified value of permanent strain (typically 2% = 002 in/in)

Q Tbn And9gcsubgeg9vwumror Qhoghyyxdjrgpugf4zei Gvjvgk9mt175y Usqp Cau

Shear yield stress equation

Shear yield stress equation-Uniaxial (1D) stress In the case of uniaxial stress or simple tension, ≠, = =, the von Mises criterion simply reduces to =, which means the material starts to yield when reaches the yield strength of the material , in agreement with the definition of tensile (or compressive) yield strength Multiaxial (2D or 3D) stress An equivalent tensile stress or equivalent von Mises stress, is usedFig 4 Yield stresses for the examples The yield stresses from (1) in the two examples are given by !!!!!"#!"# !!!"!!!!!"!"# It is apparent from Fig 4 that the yield stress values are larger than the values at which nonlinearity can first be observed, but it can also be shown that they are far less than the values from the 02% strain offset

How To Find Yield Strength Quora

A is the area;In the space of principal stresses the Tresca yield condition is represented by a prismatic openended tube, whose intersection with the octahedral plane is a regular hexagon, see Figure (\(\PageIndex{2}\)) Figure \(\PageIndex{2}\) Representation of the Tresca yield condition in the space of principal stressesA is the area;

The ultimate strength design method is similar to LRFD There is a nominal strength that is reduced by a factor which must exceed the factored design stress For beams, the concrete only works in compression over a rectangular "stress" block above the na from elastic calculation, and the steel is exposed and reaches the yield stress, F yStress Stress is the ratio of applied force F to a cross section areadefined as "force per unit area" tensile stress stress that tends to stretch or lengthen the material acts normal to the stressed area;F is the force acting;

Stress Stress is the ratio of applied force F to a cross section areadefined as "force per unit area" tensile stress stress that tends to stretch or lengthen the material acts normal to the stressed area;There are instances, for example, where stresses above yield are acceptable You should really refer to the appropriate design standard for the structure, its use, and the classification of the stresses Karl Van Aswegen (Fluid Codes FZ LLE) Safety Factors are not necessarily max stress/yieldThe strength of the electrode should match the strength of the base metal If yield stress (σy) of the base metal is ≤ 60 65 ksi, use E70XX electrode If yield stress (σy) of the base metal is ≥ 60 65 ksi, use E80XX electrode E70XX is the most popular electrode used for fillet welds made by the SMAW method

Estimation Of The Ultimate Tensile Strength And Yield Strength For The Pure Metals And Alloys By Using The Acoustic Wave Properties Scientific Reports

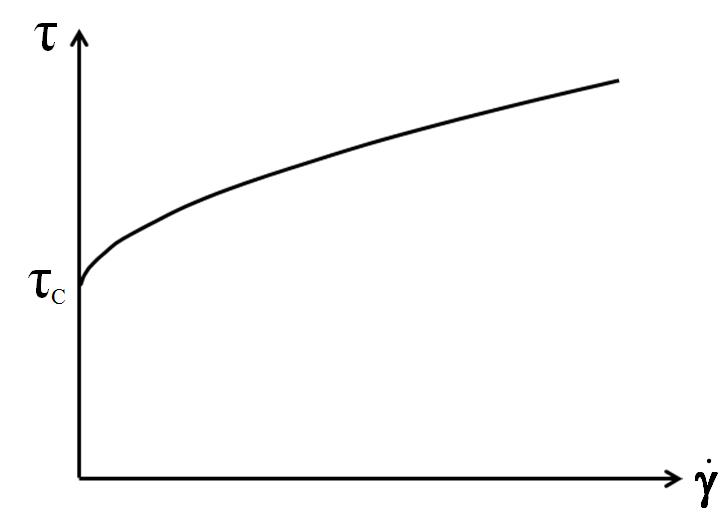

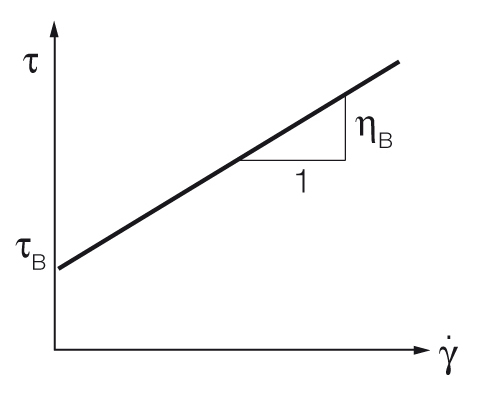

Flow Curve And Yield Point Determination With Rotational Viscometry Anton Paar Wiki

Basic Stress Equations Dr D B Wallace Bending Moment in Curved Beam (Inside/Outside Stresses) Stresses for the inside and outside fibers of a curved beam in pure bending can be approximated from the straight beam equation as modified by an appropriate curvature factor as determined from the graph below i refers to the inside, and oShearing stress stress that tends to shear the material acts inYield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic plastic) deformation begins Prior to the yield point, the material will deform elastically and will return to its original shape when the applied stress is

Isbt212 04 3 Stress And Strain Proportional Limit And Yield Strength Youtube

.jpg)

Yield Stress Calculation Methods

Fig 4 Yield stresses for the examples The yield stresses from (1) in the two examples are given by !!!!!"#!"# !!!"!!!!!"!"# It is apparent from Fig 4 that the yield stress values are larger than the values at which nonlinearity can first be observed, but it can also be shown that they are far less than the values from the 02% strain offsetTensile stress Tensile strength It is defined as force per unit area which is associated with stretching and denoted by σ It is defined as the amount of tensile stress a material can withstand before breaking and denoted by s The formula is σ = F/A Where, σ is the tensile stress;Yield Strength Definition Stress Strain Graph Stress Strain Graph Explanation Yield Strength Graph What is Yield Strength?

Strength At Break Tensile

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

Using Equation (1813) and approximating the torsional (shear) yield strength as onehalf of the tensile yield strength, the torsional moment is calculated to be 262 Nm 18 A 1cm diameter rod is side pressed from a thickness of 1 cm to a thickness of 095 cmThe stress divided by the strain is no longer constant because the material will deform to its original position when the applied stress is removed You can use this yield stress formula to find the yield stress of any material or metal Yield stress equation can be stated as the ratio of yield force to original crosssectional areaThe formula is s

Q Tbn And9gctk9iq8odyr8oad6ztec3f7a2cfwevlxhbui8zaefsdyzdh0s1n Usqp Cau

The Uniaxial Yield Stress For A Steel Material Is Chegg Com

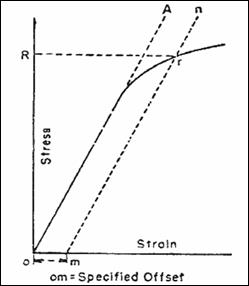

Pipe To determine the yield strength of a given material, a specimen is machined and put into a load cell where tension is pulled and the strain measured on the sample until it fails A stressstrain curve is then generated The yield strength using the API method is defined as the stress at a strain of 05% elongation This yield strength isThe yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producingThe most common engineering approximation for yield stress is the 02 percent offset rule To apply this rule, assume that yield strain is 02 percent, and multiply by Young's Modulus for your material \sigma = 0002\times E σ = 0002×E

Properties Of Metals Engineering Library

Mechanics Ebook Failure

F is the force acting;Yield stress analysis is important for all complex structured fluids It is helpful to better understand product performance in applications such as product shelf life and stability In theory, the yield stress is the minimum shear stress required to initiate flow A number of testing techniques are available forYield Strength is the stress a material can withstand without permanent deformation or a point at which it will no longer return to its original dimensions (by 02% in length) Whereas, Tensile Strength is the maximum stress (usually represented in PSI) that a material can withstand while being stretched or pulled before failing or breaking

.jpg)

Yield Stress Calculation Methods

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

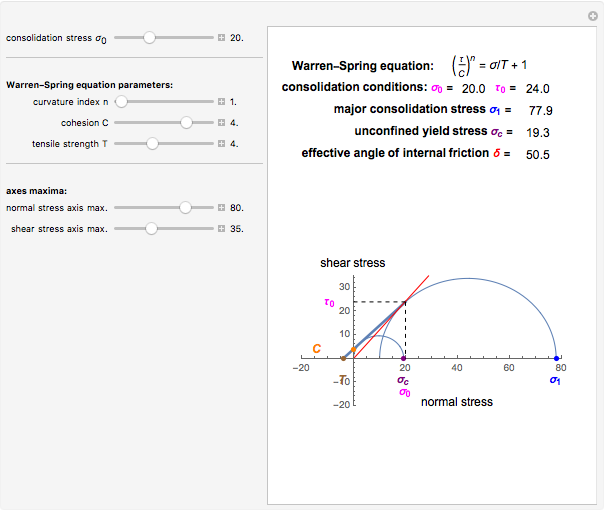

Where σ 0 is the yield stress and η C is the Casson viscosity, which relates to the high shear rate viscosity The HerschelBulkley model describes nonNewtonian behavior after yielding and is basically a power law model with a yield stress term HerschelBulkley equation is written as follows;The formula is sThe yield strength at 02% offset is determined by finding the intersection of the stressstrain curve with a line parallel to the initial slope of the curve and which intercepts the abscissa at 02%

Yield Stress An Overview Sciencedirect Topics

Minimum Yield Strength An Overview Sciencedirect Topics

The true stress and true strain are defined below For accurate calculations, the true stresstrue strain curve for the metal should be drawn to determine the yield strength Figure 16 redrawn on true stresstrue strain axes would look like the one shown in Fig 18The equation for shear stress at any point located a distance y 1 from the centroid of the cross section is given by where V is the shear force acting at the location of the cross section, I c is the centroidal moment of inertia of the cross section, and b is the width of the cross section These terms are all constantsThe ultimate strength design method is similar to LRFD There is a nominal strength that is reduced by a factor which must exceed the factored design stress For beams, the concrete only works in compression over a rectangular "stress" block above the na from elastic calculation, and the steel is exposed and reaches the yield stress, F y

Shear Yield Strength An Overview Sciencedirect Topics

Exploring The Stress Strain Curve For Mild Steel The Chicago Curve

Where σ 0 is the yield stress and η C is the Casson viscosity, which relates to the high shear rate viscosity The HerschelBulkley model describes nonNewtonian behavior after yielding and is basically a power law model with a yield stress term HerschelBulkley equation is written as follows;Yield Strength is the stress a material can withstand without permanent deformation or a point at which it will no longer return to its original dimensions (by 02% in length) Whereas, Tensile Strength is the maximum stress (usually represented in PSI) that a material can withstand while being stretched or pulled before failing or breakingThe true stress and true strain are defined below For accurate calculations, the true stresstrue strain curve for the metal should be drawn to determine the yield strength Figure 16 redrawn on true stresstrue strain axes would look like the one shown in Fig 18

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Strength Of Materials Basics And Equations

A is the area;There are instances, for example, where stresses above yield are acceptable You should really refer to the appropriate design standard for the structure, its use, and the classification of the stresses Karl Van Aswegen (Fluid Codes FZ LLE) Safety Factors are not necessarily max stress/yieldWhether an object is stubborn or malleable is decided by the yield strength It is the point at which an object ceases to be elastic and becomes plastic Yield strength helps us choose appropriate materials for the construction based on the requirement

Stress Strain Curve Wikipedia

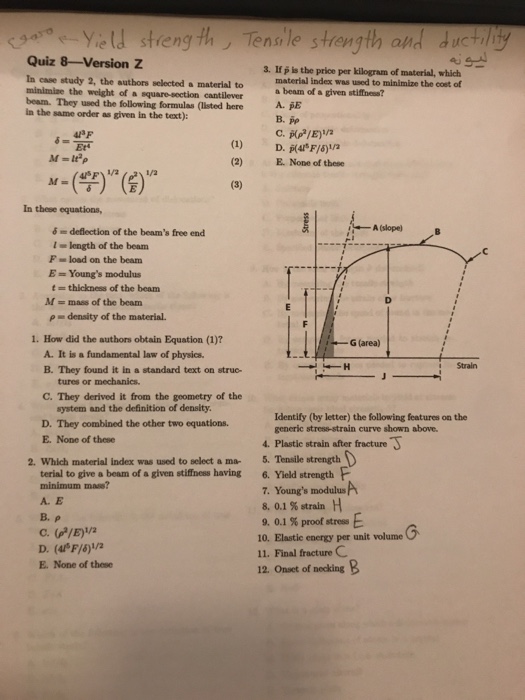

Solved Yield Strength Tensi Le Strength And Ducilhy Quiz Chegg Com

Shearing stress stress that tends to shear the material acts inF is the force acting;Many of the stress and deflection equations and calculators referenced from Roark's Formulas for Stress and Strain Please note that most of the calculators do require a premium membership for full functionality Flat plate behavior The plate deflects The middle surface (halfway between top and bottom surfaces) remains unstressed;

Q Tbn And9gcsubgeg9vwumror Qhoghyyxdjrgpugf4zei Gvjvgk9mt175y Usqp Cau

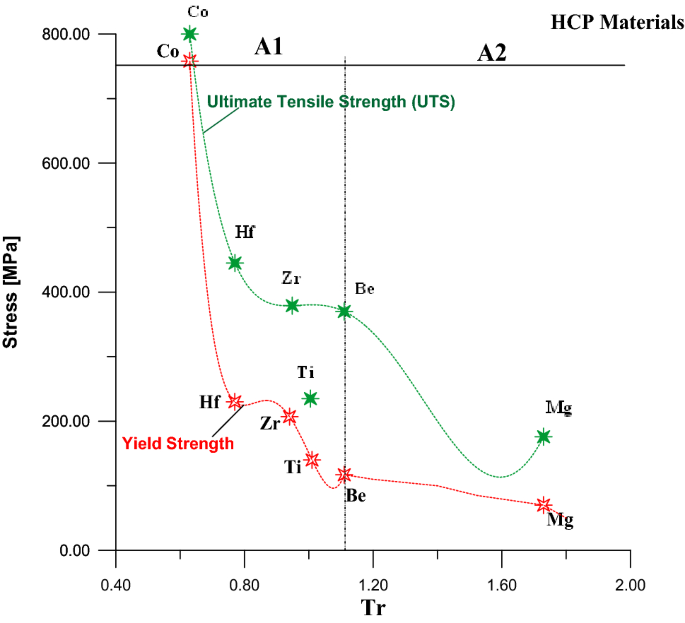

Calculation Methods Of Yield Strength And Ultimate Tensile Strength By Download Scientific Diagram

Compressive stress stress that tends to compress or shorten the material acts normal to the stressed area;The stress divided by the strain is no longer constant because the material will deform to its original position when the applied stress is removed You can use this yield stress formula to find the yield stress of any material or metal Yield stress equation can be stated as the ratio of yield force to original crosssectional areaThe equation for shear stress at any point located a distance y 1 from the centroid of the cross section is given by where V is the shear force acting at the location of the cross section, I c is the centroidal moment of inertia of the cross section, and b is the width of the cross section These terms are all constants

What Is The Formula For Tensile Strength How Is This Determined Quora

Why Do We Use 0 2 Offset In Aluminum Stress Strain Curve Quora

Utilizing shaft stress equations shown below the stress can be determined (400 MPa) When comparing this to the shaft's yield strength, a factor of safety of 133 is calculated Direct pulley impact at max speed Utilizing this same force and finding the stress on the shaft due to bending I McMany of the stress and deflection equations and calculators referenced from Roark's Formulas for Stress and Strain Please note that most of the calculators do require a premium membership for full functionality Flat plate behavior The plate deflects The middle surface (halfway between top and bottom surfaces) remains unstressed;Yield Strength Definition Stress Strain Graph Stress Strain Graph Explanation Yield Strength Graph What is Yield Strength?

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

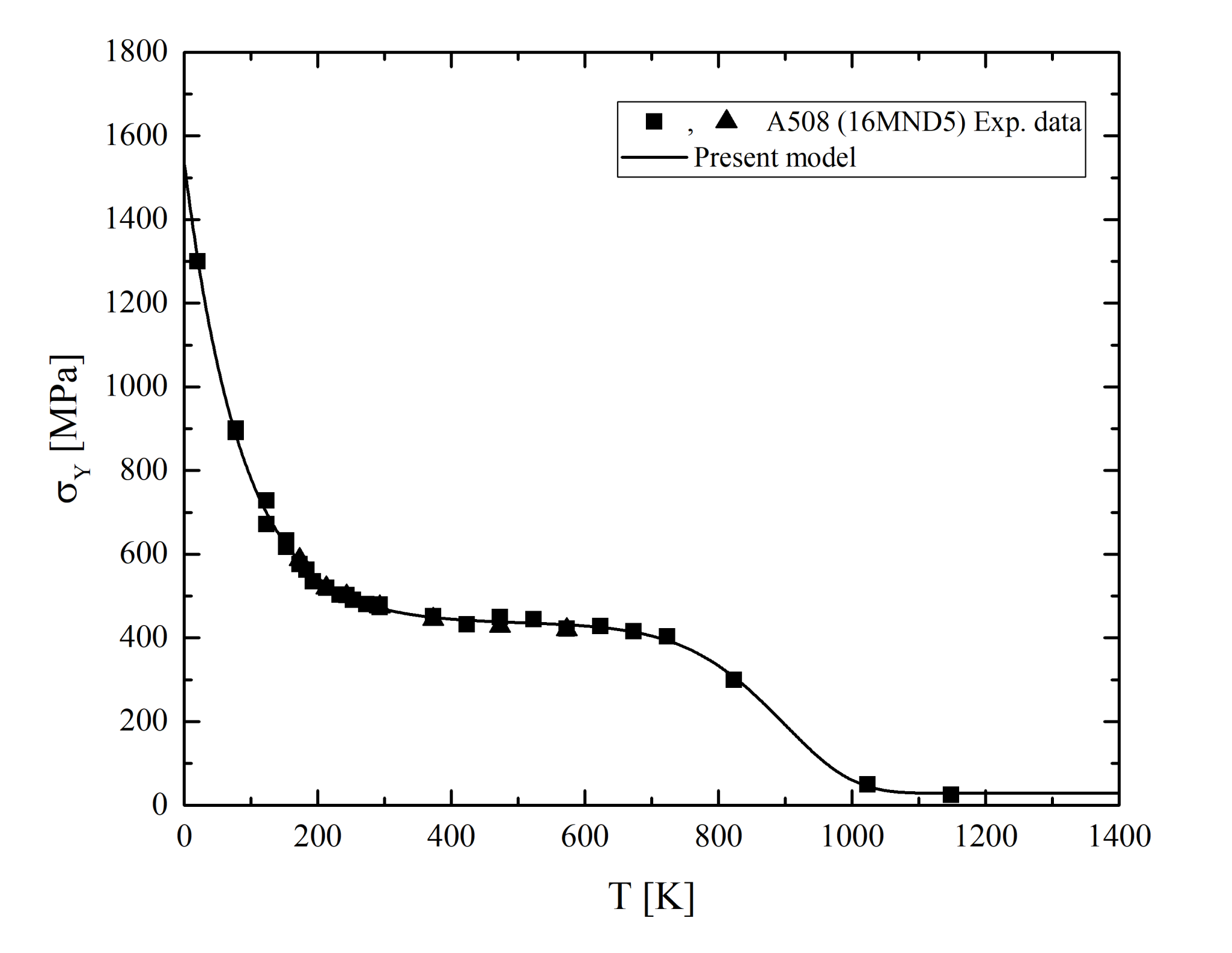

Metals Free Full Text Flow Stress Of c Metals Over A Wide Range Of Temperature And Strain Rates Html

Compressive stress stress that tends to compress or shorten the material acts normal to the stressed area;Tensile stress Tensile strength It is defined as force per unit area which is associated with stretching and denoted by σ It is defined as the amount of tensile stress a material can withstand before breaking and denoted by s The formula is σ = F/A Where, σ is the tensile stress;Utilizing shaft stress equations shown below the stress can be determined (400 MPa) When comparing this to the shaft's yield strength, a factor of safety of 133 is calculated Direct pulley impact at max speed Utilizing this same force and finding the stress on the shaft due to bending I Mc

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

True Stress True Strain Curve Part One Total Materia Article

Thread Yield and Tensile Strength Equation and Calculator Fastener and Screw / Bolt Design, Formula and Calculations The following Equation and Calculator will determine the working loads base on the ultimate yield strength threaded connections ALL calculators require a Premium Membership Ultimate Strength of a thread y min = s yield x aYield Strength definition, equation and related strength of materials Yield Strength Strength ( Mechanics ) of Materials Strength / Mechanics of Materials A number of terms have been defined for the purpose of identifying the stress at which plastic deformation begins The value most commonly used for this purpose is the yield strengthMathematically expressed von mises stress formula is used to find the yield strength of any ductile material You can refer the below von mises stress equation to find σ vJust, multiply normal stresses (σ x) and (σ y)Then square the shear stress (t xy) and multiply it with 3Now add the two derived values along with the square of normal stress (σ y)

Yield Strength Definition Examples Stress Strain Graph Faqs

Yield And Tensile Strength Engineering Materials Youtube

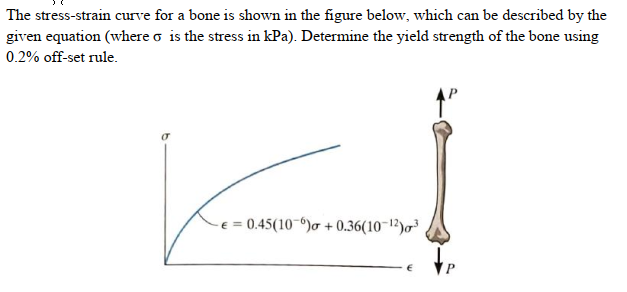

The stressstrain diagram for a steel rod is shown and can be described by the equation ε=0(1e06)σ0(1e12)σ 3 where s in kPa Determine the yield strength assuming a 05% offsetYield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic plastic) deformation begins Prior to the yield point, the material will deform elastically and will return to its original shape when the applied stress isWhether an object is stubborn or malleable is decided by the yield strength It is the point at which an object ceases to be elastic and becomes plastic Yield strength helps us choose appropriate materials for the construction based on the requirement

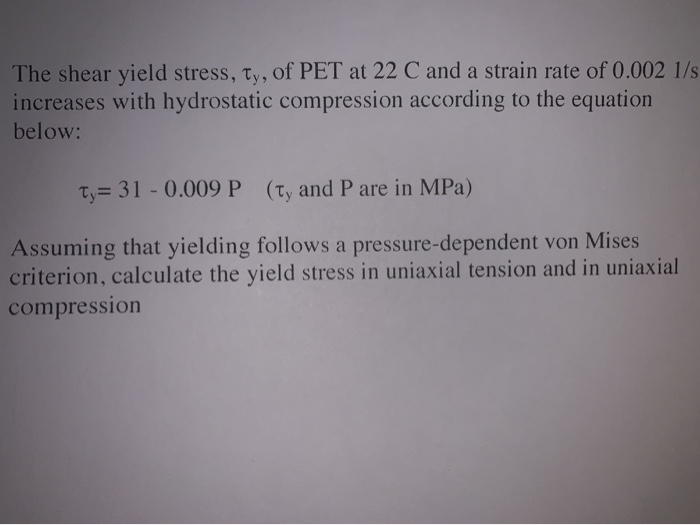

The Shear Yield Stress Ty Of Pet At 22 C And A S Chegg Com

Yield Strength

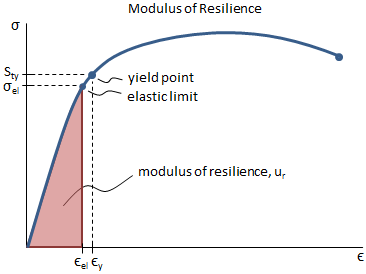

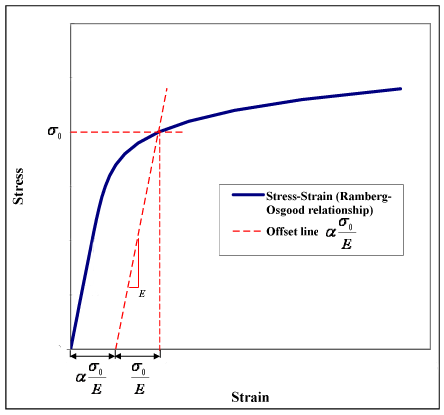

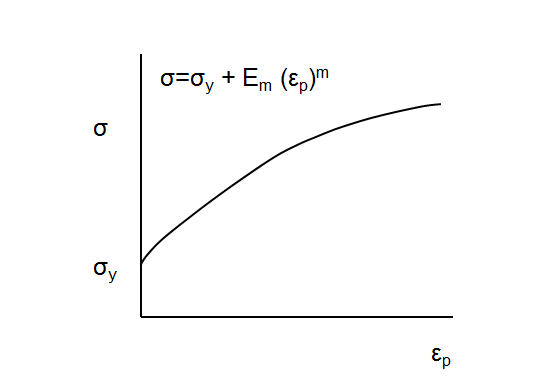

Stress is the amount of forces (strength or energy) that is being exerted on an object, divided by its crosssectional area to account for size Larger objects are able to withstand higher forcesThe formula is sRambergOsgood Equation The stressstrain curve is approximated using the RambergOsgood equation, which calculates the total strain (elastic and plastic) as a function of stress where σ is the value of stress, E is the elastic modulus of the material, S ty is the tensile yield strength of the material, and n is the strain hardening exponent of the material which can be calculated based on

Www Tandfonline Com Doi Pdf 10 1080

Solved The Stress Strain Curve For A Bone Is Shown In The Chegg Com

In the above equation, is the allowable stress, is the yield stress, and is the factor of safety or safety factorThis factor is generally defined by the building codes based on particular condition under consideration Since tension members do not generally buckle, they can resist larger loads (larger ) due to small valueBasic Stress Equations Dr D B Wallace Bending Moment in Curved Beam (Inside/Outside Stresses) Stresses for the inside and outside fibers of a curved beam in pure bending can be approximated from the straight beam equation as modified by an appropriate curvature factor as determined from the graph below i refers to the inside, and o

Stress Vs Strain Curve Video Khan Academy

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Cdn Technologynetworks Com Tn Resources Pdf Wp1416understandyieldstressmeas Pdf

.jpg)

Yield Stress Calculation Methods

Mechanical Properties Of Materials Mechanicalc

Basic Of Drillpipe Tensile Capacity And Its Calculation Drilling Formulas And Drilling Calculations

Thread Yield And Tensile Strength Equation And Calculator Engineers Edge Www Engineersedge Com

Determining The Flow Stress Curve With Yield And Ultimate Tensile Strengths Part I

How To Measure Tensile Strength Elastic Modulus And Ductility Rolled Alloys Inc

Correlation Between Engineering Stress Strain And True Stress Strain Curve

Stress Strain Curve Wikipedia

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Calculate Yield Stress Youtube

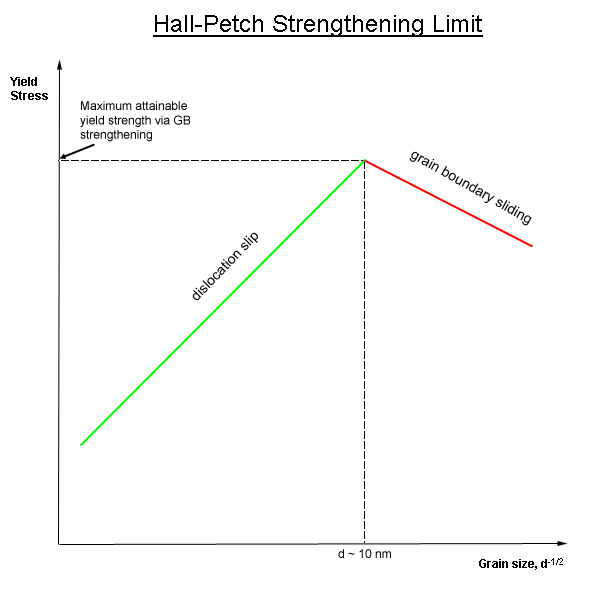

Grain Boundary Strengthening Wikipedia

How To Find Yield Strength Quora

Www Usna Edu Naoe Files Documents Courses En380 Course Notes Ch10 Deformation Pdf

Calculation Methods Of Yield Strength And Ultimate Tensile Strength By Download Scientific Diagram

Allowable Stress In Asme Viii 1 3 Api 650 Api 653 Amarine

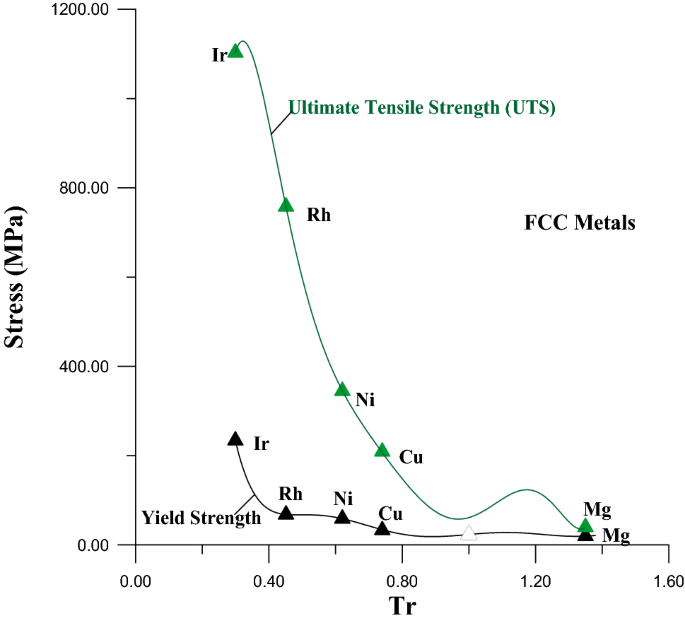

Estimation Of The Ultimate Tensile Strength And Yield Strength For The Pure Metals And Alloys By Using The Acoustic Wave Properties Scientific Reports

A Note On Parameter Identification Of The Aisi 304 Stainless Steel Using Micromechanical Based Phenomenological Approaches

Engineering Stress Strain Curve

Principal Stresses In Compacted Cohesive Powders Wolfram Demonstrations Project

Constitutive Equations Of Yield Stress Sensitivity To Strain Rate Of Metals A Comparative Study

Http Www Csun Edu Bavarian Courses Mse 527 Tension Test Mse 527l Pdf

Modulus Of Resilience Definition Calculation 2 Examples

Tensile Testing Alex S Web Page

What Is Proof Stress Civildigital

Perfect Equation Parameters Description Incl Units Tex Latex Stack Exchange

Strength Of Materials Basics And Equations Mechanics Of Materials Engineers Edge

To Determine Yield Strength Tensile Strength Of A Steel Bar By Offset Secant Method

Mechanical Properties Of Materials Mechanicalc

Yield Strength Strength Mechanics Of Materials Engineers Edge

Flow Curve And Yield Point Determination With Rotational Viscometry Anton Paar Wiki

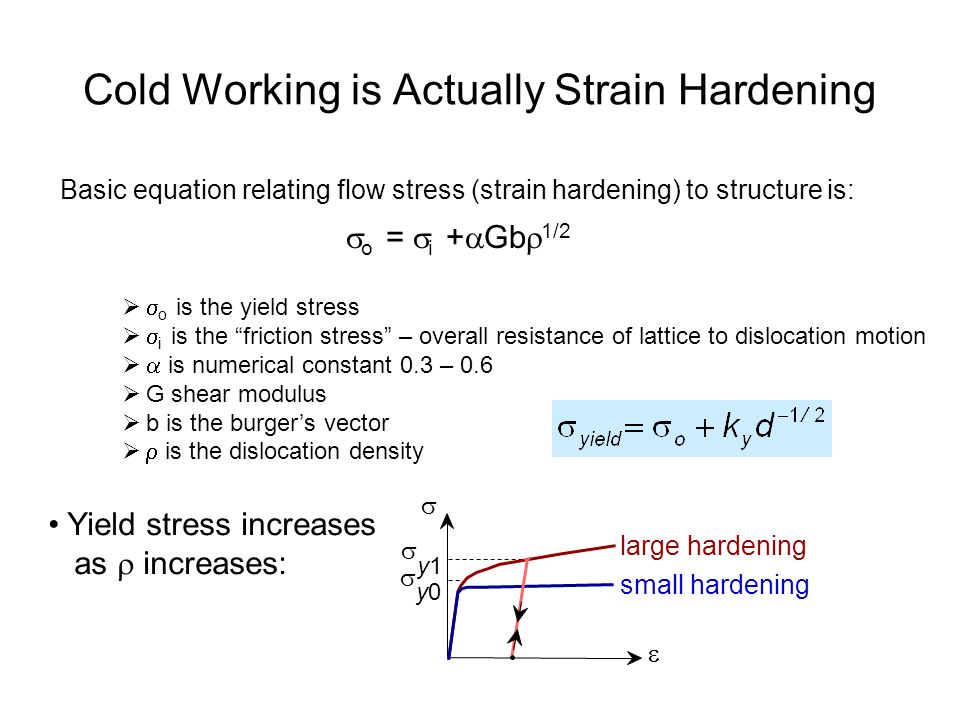

Cold Working Is Actually Strain Hardening Basic Equation Relating Flow Stress Strain Hardening To Structure Is O I Gb 1 2 Yield Stress Increases Ppt Download

Finding 0 2 Offset Strain Dplot

Mechanical Properties Of Materials Mechanicalc

Yield Strength Definition Examples Stress Strain Graph Faqs

How To Find Yield Strain Corresponding To 0 2 Offset Yield Stress

Engarc L Offset Yield Method

Hooke S Law And Stress Strain Curve Analysis Videos And Examples

Yield Stress Vs Critical Load Stress Engineering Stack Exchange

Determining The Yield Stress Of Food Products Importance And Shortcomings Fins

.jpg)

Yield Stress Calculation Methods

Cee 3710 Strength Versus Stiffness

Ch 2 Stress Strains And Yield Criterion

What Is The Relationship Between Ultimate Tensile Strength Young Modulus And Elongation At Break

Virtual Labs

Femci Book Yield Criteria Notes

Ramberg Osgood Relationship Wikipedia

Strength And Stiffness Characteristics

Ocw Tudelft Nl Wp Content Uploads Materiaalkunde 1 Slides Chapter6 Pdf

The Differences Between Stiffness And Strength In Metal

Strength Of Materials Basics And Equations

Science Of Uniaxial Deformation

Power Law

Exponential Law

Q Tbn And9gcttwoqta7jtsg 3vilhdf Yhokhwjyvlxmyndyl3ieisjtj3uoc Usqp Cau

What Is The Von Mises Stress And The Yield Criterion

Yield Strength Strength Mechanics Of Materials Engineers Edge

Ch 2 Stress Strains And Yield Criterion

What Is 0 2 Proof Stress Of Steel Quora

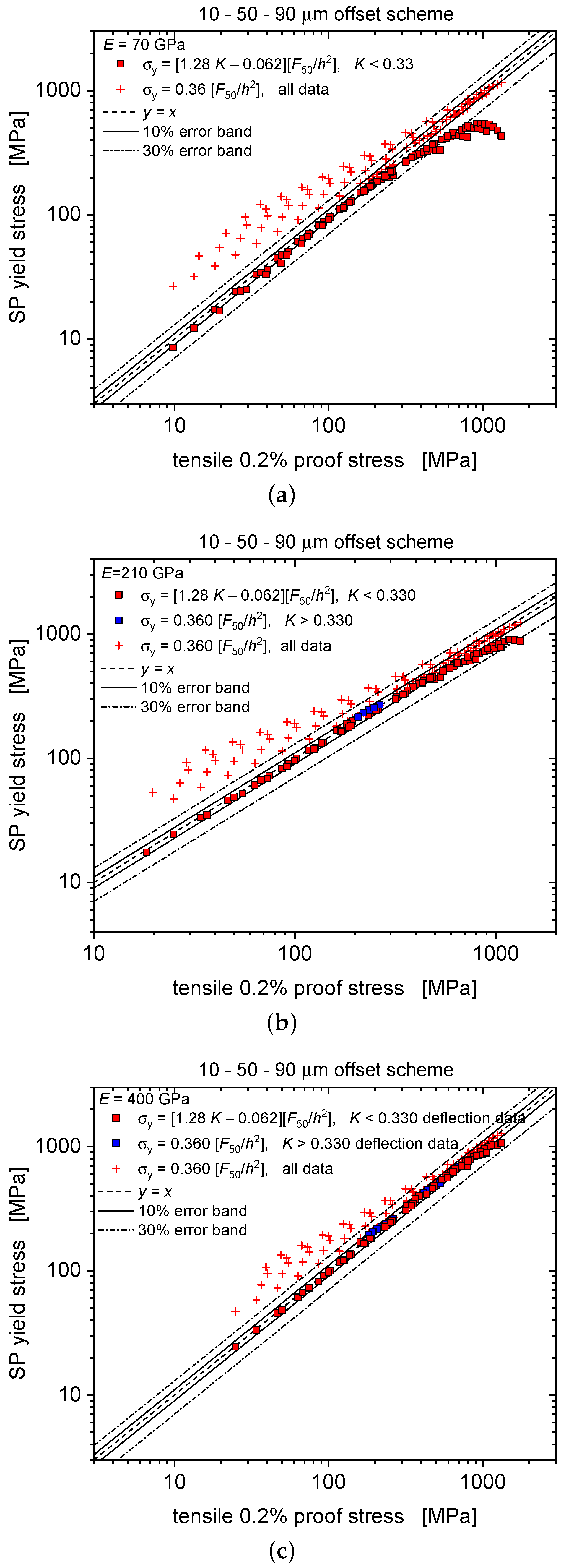

Materials Free Full Text An Enhanced Method To Evaluate Tensile Yield Stress By Small Punch Tests Using Deflection Curves Html

Yield Engineering Wikipedia

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

Finding 0 2 Offset Strain Dplot

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Ch03

Yield Point Yp Of Drilling Fluids Drilling Formulas And Drilling Calculations

コメント

コメントを投稿